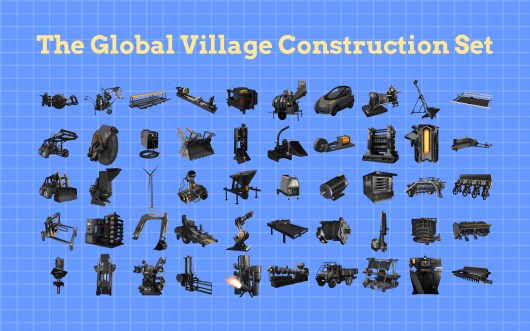

Founder of Open Source Ecology Marcin Jakubowksi is creating open blueprints for the building blocks of civilization, starting with the Global Village Construction Set. This set of 50 low-cost machines will allow anyone to build all the infrastructure a community needs – including, at Factor E Farm, one of his own.

The Global Village Construction Set is wildly ambitious idea. How did you get to it?

In childhood, I always thought about technology. My father’s a scientist and my mother’s a teacher, and early on I felt science was an incredible human invention that should be able to make life good for everybody. So I always wanted to do something awesome with technology.

But the further I went in my education system, the less useful I felt. By the second year into my PhD in fusion energy, I felt alienated from the work I was doing: I still thought fusion would be the solution to human energy problems, but the more I looked into it, the more I realized it wasn’t the answer. It’s got a lot of issues, including radioactivity and the fact that it’s another centralization technology. I felt it would not contribute to an honest solution to a sound technology base for humans. So I started thinking, “Well, what is a sound technology base? And how can we thrive with the amazing technology that we have?”

This is how the Global Village Construction Set originated. What if we were to start from scratch? Can we create communities that are truly spectacles of human progress that don’t end up getting wrapped up in all the geopolitics and compromises we have in society today?

How did you decide to make it open source?

While I was working on my PhD, I noticed I couldn’t talk openly to other groups because we had some hot material. So I thought, “Wow. Even in academia I can’t collaborate openly.” I felt this limitation was simply reducing my ability to learn — such an opportunity wasted.

The Open Source Ecology concept comes from trying to answer the question, “What happens when you truly collaborate openly with others?” That applies to all the sectors of society, from business to everything else. At the moment, most people don’t work together. Each company has its own proprietary R&D department. There’s a lot of reinventing the wheel going on. I feel that if we simply collaborated, we could accelerate progress by 10- to 100-fold.

That’s the essence of open-source: we’re trying to build on what already exists, and then contributing back to that and letting everybody benefit from it, as opposed to benefiting only a few. So it’s a shift in a mindset from zero-sum game to post-scarcity.

What are the machines, and why are they the essential building blocks for civilization?

The set of machines I’m developing covers agriculture, energy, transportation, production — essentially every piece of human infrastructure we rely on to provide a modern standard of living. Do you eat? Yeah, you eat. So you need agricultural equipment to feed people optimally — everything from a tractor to a bakery oven. What other tools might we need? A circuit maker, industrial robots, renewable energy equipment, construction equipment, fabrication equipment. For transportation, a car — a 100-mile-per-gallon renewable energy car, which will run on a modern steam engine using pelletized biomass as a renewable energy source. Algae could potentially work, as well. For renewable energy, we are working on a solar concentrator that’s essentially a point-focus dish-like system made of multiple mirrors, but on a 5-to50-kilowatt unit scale. These are scalable and modular, so we can build a number of them and produce a lot of power.

All our designs are modular. For example, you can detach the wheel units on the tractor by turning a lever, pulling one bolt, and detaching the wheel for use on another device such as a micro-tractor or a truck or a bulldozer, maximizing the flexibility of the package.

With the fabrication part of this technology infrastructure — computer-aided fabrication, things like CNC torch tables or precision machining, circuit mills and 3D printers — products can be designed in a LEGO-like fashion. We focus a lot on bolt-together, modular design. In principle, that’s what we’re aiming for. Once we optimize the designs, I would say in about one month with, say, four people, you can produce everything using advanced fabrication machinery: tractors, cars, bulldozers, backhoes, agricultural combines, cement mixers, well-drilling rigs — about 30 different mechanical devices in a month’s time with super-efficient production. I need to emphasize that we haven’t accomplished this yet — but the evidence that we have gathered so far indicates that this will be the reality of efficient, distributed, open-source production.

Where do you find the material for all these machines?

Right now, we buy materials off the shelf. But part of the set includes an induction furnace and hot metal rolling processes. So you can actually take scrap steel, melt it down, and roll it out into virgin steel. So any place that has a scrap metal yard, you can take that and essentially reboot civilization from there.

Wow! So this is essentially the kit for the Apocalypse.

That’s what some people say. I look at it as lowering the barriers to entry for enterprise. What I want to use it for is to build a real community. That’s what Factor e Farm is. We’ve got 30 acres in Missouri, and we’re building a solid team where we’re simultaneously developing tools and using them to build a community. Right now we have 14 people living on the farm. By the end of next year, we want to raise the population up to 24. The challenge is finding the right people.

You’ll need other resources to get started, too, such as seeds.

Yes, you need some seeds. If you do perennial agriculture, then you can grow out the entire genetic stock and then propagate it using a nursery. If you need glass, you have sand. If you have sand you have silicon, which is the digital age. If you have clay, you have aluminosilicate, or aluminum, which is a substance of modern civilization — metals. Actually, the aluminum extractor is one of the more advanced tools in the set.

Is Factor e Farm’s goal self-sufficiency?

It’s autonomy. We’re looking at it from the standpoint of social enterprise. We’re creating tools that can allow people to produce just about anything. At the moment, we’re developing the tools, but our ultimate goal is to train people to be social entrepreneurs that can create anything from an open source Fab Lab to an organic farm to a research facility.

How many of the machines have you already finished?

We’ve got four beta releases of machines — a tractor, a brick press, a soil pulverizer and a hydraulic power unit. All together, we’ve got about 15 prototypess including the CNC circuit mill, CNC torch table, micro-tractor, cement mixer, dimensional sawmill, ironworker machine and heat exchanger. We’re working currently on the modern steam engine.

All our machines are open source — anyone can download the designs and budgets. But we are also selling our machines readymade. We’re working on optimized production to the point where we can sell compressed earth brick presses to earn $20,000 per month, allowing us to bootstrap-fund further development. We are streamlining fabrication such that eight people can produce one press in one day with collaborative production. It costs $4,000 in the materials, and we sell the presses for $9,000 — clearing about $5,000 per machine. We plan to have four production runs per month, and the rest of the time we’ll spend developing the kit and the community. People are contacting me all the time about getting the brick presses, so we have a market. Most of the time I have to tell them, “Hey, download the plans, have your fabricator build it. We’re building capacity right now.”

What about the Factor e Farm community?

We’re recruiting more people to join us. Our goal is to get our population to 24 people by the end of 2013. We now have a farm manager onsite, so we’re beginning full agriculture so we can produce local food. We aim to build studios from compressed block — 300 square feet — in one week, including real-time pressing and laying. We just built a 4,000 square foot living unit for 10 people — double brick walls with straw insulation in between. We’re off-grid, but we’ve got flush toilets, electricity. We also have a composting toilet — different options for different people.

There’s a little bit of a gender imbalance. We’ve got one woman, on site. So we encourage women to join. And we’re building the community. And that’s where we’re at right now. Next, we need to nail down the strategic plan and a business plan, because there are many different directions we can go with this.

What kind of people are you looking for?

We basically look for people who are lifestyle-motivated people who want to set up similar operations, and they are direct stakeholders. Our farm director wants to be a farmer eventually, and she’s learning all the tools and techniques. Our production director wants to start a facility in another location once he’s done here. So we’re looking for people who really want to use the tools themselves. We pay people with skills and access to the technologies that they would otherwise have to pay money for. That’s the lifestyle-investorship model – where we’re trying to get people who are really interested, so they have the motivation and the willingness to work hard to make this a reality. We can also pay people for talent that we couldn’t get otherwise.

Psychologically speaking, this is an interesting experiment.

That is the most interesting part. That, in fact, is going to be the biggest challenge. The technology is easy. It doesn’t have a mind of its own. But with people, we’re noticing that as we develop the experiment, we also have to train the people for mental health. You’ve got to be a mature person. Your mindset has to evolve from a zero-sum game to post-scarcity. It’s a lot about personal growth. It’s huge — this is simply getting to the evolution of people as human beings.

I think a lot about integrated humans and life/work integration. Why aren’t people really working where they live or making their life their passion and work? What we do is our passion. That level of integration is the real benefit of what this can provide. That’s on a more philosophical level, and it’s also very practical for me. I’m living that right now and pursuing my passion. And I have a low-cost environment to make that happen in a responsible way.

How far can you go with this? Looking way forward, at some point you’ll need healthcare, education…

Absolutely. Right now we’re simply starting with the basics of infrastructure. The next things are education, health, financial systems, governance. The medical stuff will probably going to be the toughest. Then we go into things like semiconductor manufacturing. Our goal is to show that on 30 acres, with 30 people — that’s not highly replicable perhaps, because they’re typically superstars — see how far we can go into creating a modern standard of living, up to things like semiconductors and metals, all from on-site resources. It’s intended to be a significant data point for what a small group of individuals can do to set a benchmark for prosperity.

How has the TED Fellowship changed the way you work?

Before TED 2011, we were running on about a $1,500 a month crowd-sourced budget. I ran out of money pretty quickly doing this. Since becoming a Fellow, we’ve got about a million hits on my TEDTalk and $500,000 of funding. Essentially all that money and most of the team onsite came through after seeing the TED Talk.

So basically since 2011, we’ve exploded and are trying to deal with the growing pains right now. It’s pretty amazing what’s happening.

How do people respond to your ideas?

There are essentially two camps. One says, “Whoa, this idea’s going to take over the world and it’s worth supporting.” A lot of people are interested in the principle.

And then there are a people who say, “If you’re open-source, you can’t scale. What’s your business model? How are you going to disseminate?” And that’s a hard question. For me the answer is clear, it’s that we’re reproducing very common items that everybody uses. If we can produce them at a lower cost — say 5 to 10 times lower — then we can be in business. We’re optimizing product design for simplicity, lifetime design, modularity, interchangeability of parts. We’re trying to tame technology. I think that’s a solid foundation.

And then people say, “Well what’s your revenue model?” We’re aiming to show that a 4,000 square foot facility — a flexible digital fabrication facility that’s part of our tool set — can net $80,000 per month with four fabricators. Our goal is to demonstrate super efficient production, which we will use to bootstrap fund ourselves and then teach others how to get into enterprise. So it’s a production and teaching model — we will replicate by teaching people the skills. They can then either start facilities like this, or set up a research center, or any kind of land-based facility. These tools can be used from rebuilding villages, to starting up education facilities, organic farms, production facilities, all kinds of things. Therefore, there is lots of potential in positioning ourselves as a distributive enterprise incubator. We will simply offer efficient, low-cost products — desirable just about anywhere in the world.

It’s also missing the point, isn’t it? Because the point isn’t to generate massive revenue, the point is to create a self-sufficient world. The goal is to be able to live how you want to live.

Absolutely. That’s exactly it. A common economic critique of our is that the market becomes efficient and runs us out of business. We can enjoy our cost advantage only for a short time as an open-source project — before others begin to compete and bring the price down. But that’s actually a mark of our success: people adopting low-cost, distributed production such that the world in general reaches a condition of material post-scarcity.

So how do we survive in the long term? As pioneers, we enjoy economic primacy and social capital initially — to the point where we are able to fund further development. We then move on to develop new machines. Then we run ourselves out of business again because we are open source. But if that is indeed the case — and if we succeed in doing this for a set of tools that can create a complete economy — then we have actually succeeded in creating a scalable model for creating economically autonomous communities. Our product is autonomy. That to me implies a better world — where material scarcity is no longer an underlying driving force for most of civilization’s dynamics. Then people can pursue higher purpose, life-work integration, and a modern standard of living that does not take us back to the stone age.

Personally, I think that with truly appropriate technology infrastructure in civilization — we can create a modern standard of living with no more than two hours of work per day, while using abundant local resources. Then– what do we do with our spare time? We focus on things that are truly important to us. That involves a complete mind shift. I am hopeful that we will evolve to this state as humans — within a generation.

Comments (1)

Pingback: Marcin Jakubowski is building the DIY machines for a new civilization | Tim Batchelder.com