Architect Alastair Parvin came to TED2013 with questions that challenge our preconceptions about building. How about we involve everyone in the architectural design process, not just professional architects building for the super-wealthy? What about a world in which cities are built by citizens?

Alastair Parvin: Architecture for the people by the people

Parvin isn’t merely being rhetorical, as he shares in today’s talk. He and his London-based team have come up with a way to democratize both the design and the manufacturing of buildings. It’s called WikiHouse.

Alastair Parvin: Architecture for the people by the people

Parvin isn’t merely being rhetorical, as he shares in today’s talk. He and his London-based team have come up with a way to democratize both the design and the manufacturing of buildings. It’s called WikiHouse.

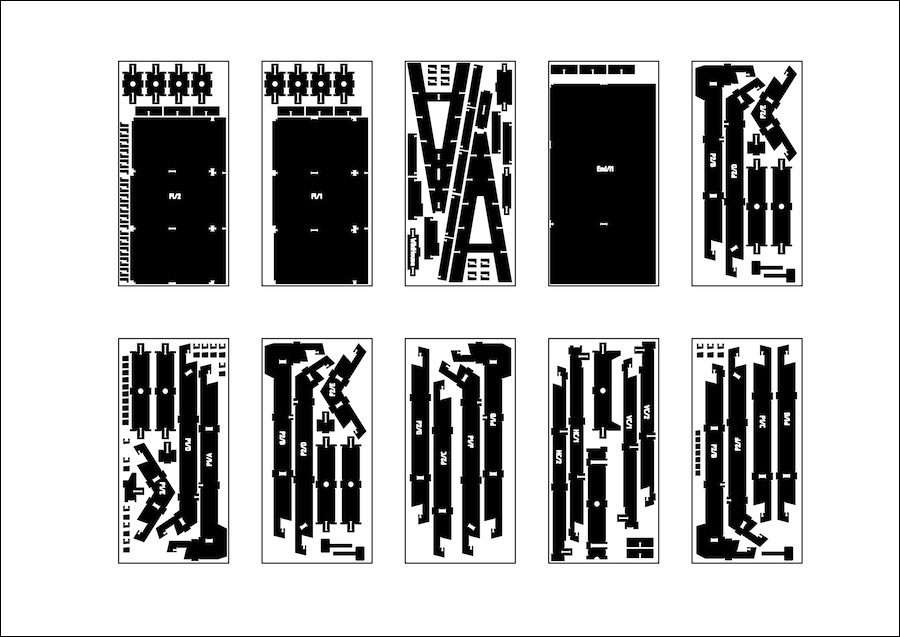

“The idea is to make it possible for anyone to go online and access a freely shared library of 3D models which they can download and adapt in Sketchup,” he says in today’s talk. “Almost at the click of a switch, they can generate a series of cutting files, which allow them in effect to print out the parts from a house using a CNC machine and a standard sheet material like plywood. The parts are all numbered, and basically what you end up with is a really big IKEA kit.”

Sounds intriguing… so how does it really work? We got Parvin to break it down, visually:

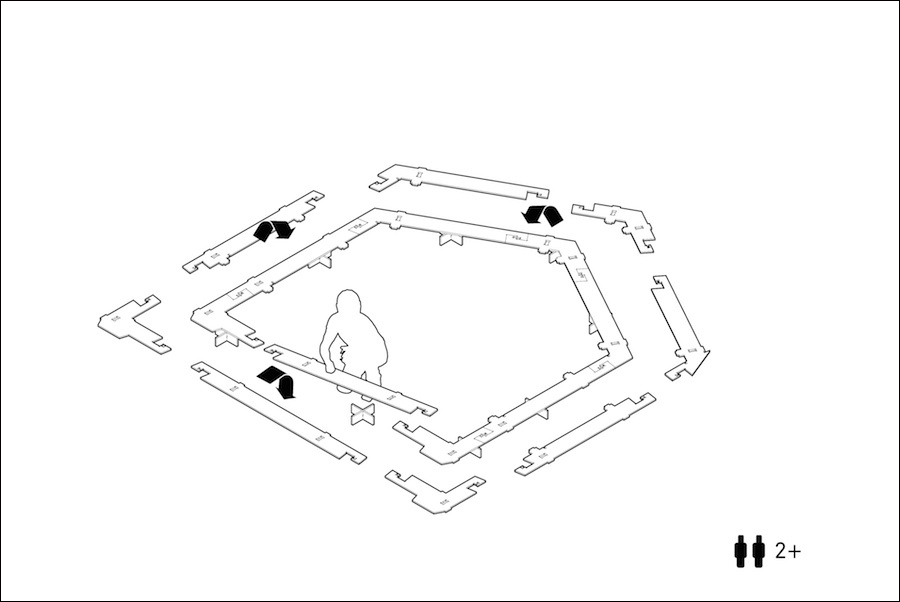

WikiHouse is an “open source construction kit.” It enables anyone with an Internet connection to access a shared library of structural designs.

Users simply choose a design. By clicking a button marked, “Make this house,” WikiHouse generates a set of cutting files for each of the parts that goes into that particular structure.

Using a CNC machine, the parts can be “printed” from a standard sheet material such as plywood.

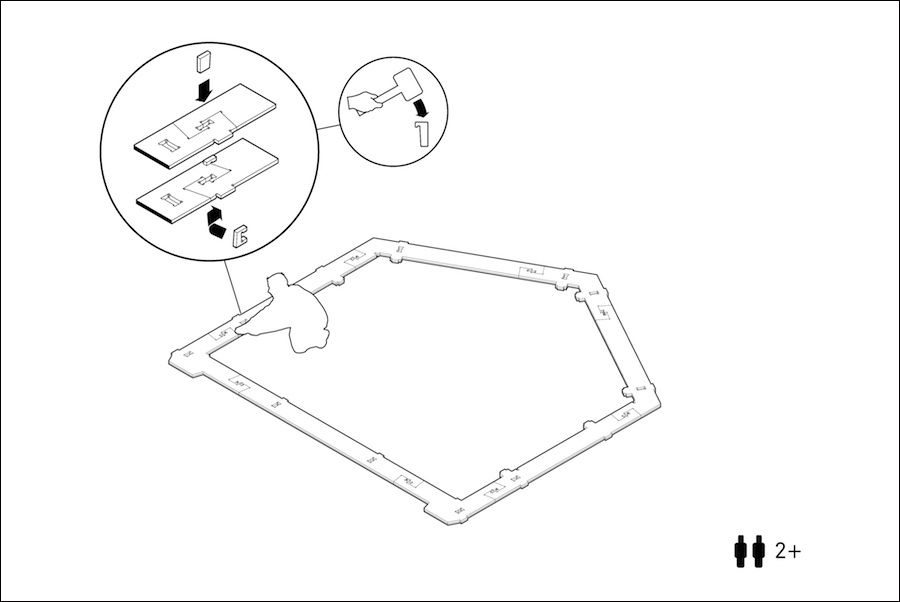

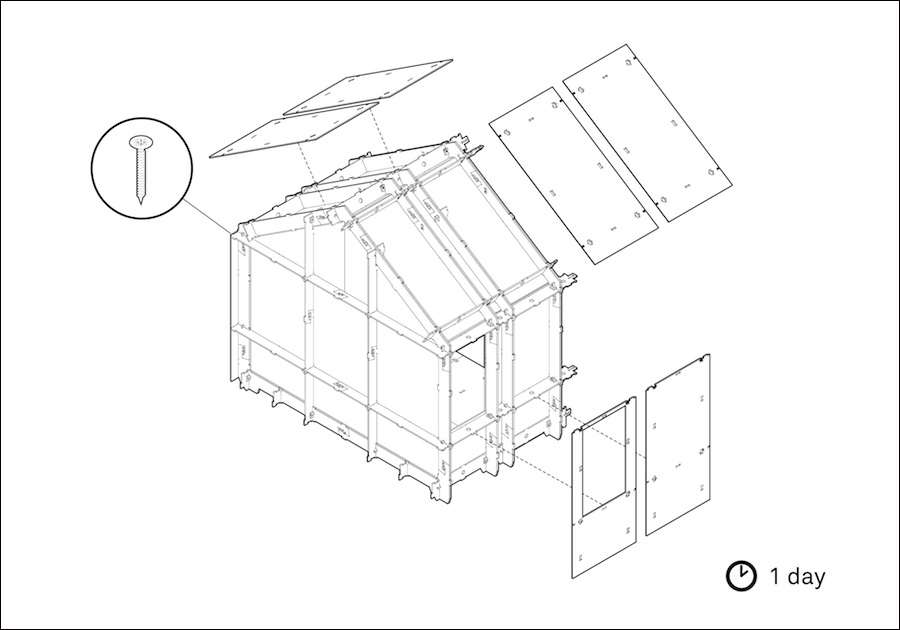

All of the parts in the open source construction kit are numbered, and designed to minimize confusion. “The principles of openness go right to the mundane physical details,” Parvin says. “Don’t design a piece that can’t be picked up, and don’t design a piece that could be put in the wrong way around.”

The WikiHouse system is designed so that it slots together using wedges and pegs. Here’s another radical idea: even the tools used to make the house can be crafted using the WikiHouse technology. Design and manufacture your own mallet!

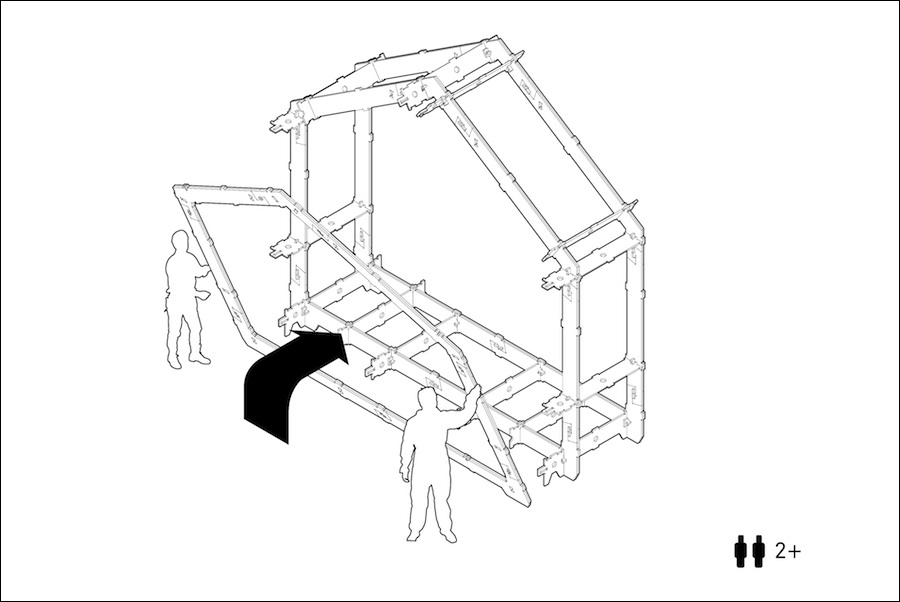

“People get confused between construction work and having fun,” jokes Parvin, who points out that before the Industrial Revolution, barn-raisings were a common occurrence. Why shouldn’t family and friends be involved in the construction of a modern house?

A building’s panels are screwed into place. A small team can complete a house structure in about a day. As Parvin lyrically describes, imagine “a future where the factory is everywhere, the design team is everyone.”

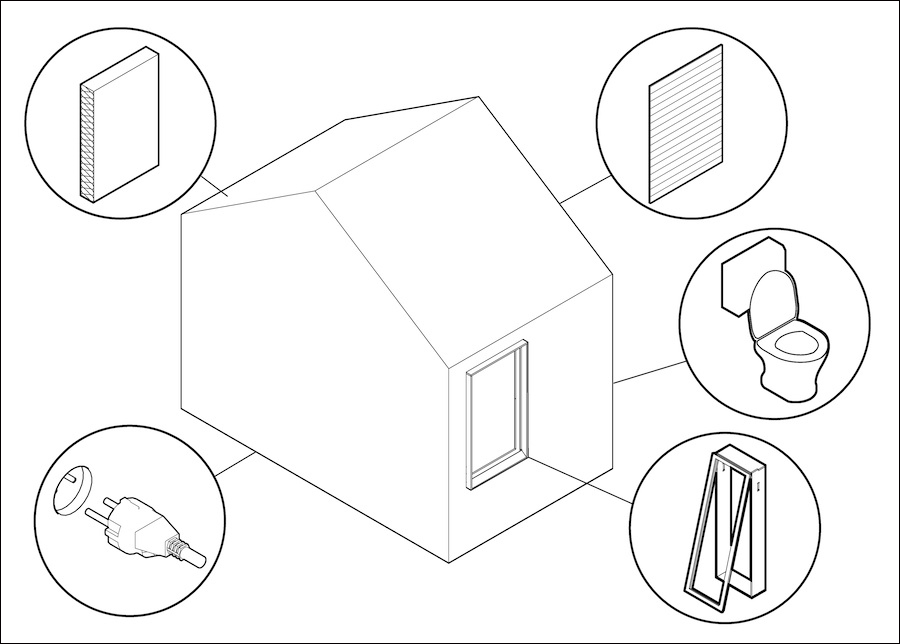

Mod cons might not be included in a WikiHouse, but they can certainly be incorporated. The frame of the house can easily be adapted to include the likes of cladding, insulation and windows as well as other amenities. Maybe one day, those will be downloadable files, too.

It’s still early days for the WikiHouse project (buildings take time to make, after all.) But here’s an intriguing timelapse video, filmed at the OUI Share Fest in Paris, which shows wiki-building at work.

Comments (13)

Pingback: Open Source Construction - The Humble Pencil : Stephan Hitchins

Pingback: WIKI HOUSE | URBANLINKLINES

Pingback: A new way of building: 3D printing | ReConstructRomania

Pingback: Yüksek Standartta Gecekondu | Yaşanabilir Şehir

Pingback: Wikihouse, en busqueda de la democratización arquitectónica | PERIODISMO DIGITAL

Pingback: Wikihouse’s Alastair Parvin on how to build your own house | TED Blog | starter

Pingback: Some assembly required: print your own house from these open-source plans » UMaine NMDNet

Pingback: DIY IKEA House | hippoblog

Pingback: Will these disrupting real estate prices? | Snippets from around...